2 more loads to go; 1/2 will be filled with doors/windows. Check out where these trucks are headed & the project that will shortly come to life. Stay tuned for more photos.

2 more loads to go; 1/2 will be filled with doors/windows. Check out where these trucks are headed & the project that will shortly come to life. Stay tuned for more photos.

Timber Home Living Magazine highlights Industry Professionals in their column Industry Insider. Their August 2014 Magazine, Jeff Bowes President & Partner of Canadian Timberframes was their focus. They interviewed him and talk about his rich history & expertise within this industry.

We are double pumping concrete in Airdrie Alberta on this 10,000 square foot home (see image below).

While the lot is getting prepped, we are working hard at hand peeling 2 40' logs and distressing and staining to match the interior timber frame finish to come later. Theses massive hand picked logs will go vertical in the home mid Nov, and will span the 2 stories of the home.

The home owners came out to our manufacturing facility in Golden, BC to hand pick the logs that will remain hand peeled & distressed inside their home as a wonderful architectural element amongst the timber frame interior.

One home owner, whom we are currently working with, does a lot of entertaining for large groups.

He designed his living area and dining room space to fit, the only problem was they could not find a dining room table large enough to 'own' the space and seat enough for their entertaining style. Solution, we designed and manufactured a dining room table to match their interior timber frame home.

This custom table stands 5' wide and 15' long. The massive timber style is suited to the interior design of this home.

Click here to view the timberframe project

To be able to show off a spectacular timber frame, every cut and every joint must be precise. Before technology, the logs for timberframe homes were all hewn, finished and joined by the hands of skilled craftsmen. And while there are still proponents of that method, CNC technology allows for precision milling in a much shorter but still labour-intensive timeframe.

“When the timbers arrive onsite, many people don’t realize the hundreds of hours of labour that have already been expended to prepare them,” explains Jeff Bowes, President and Partner at Canadian Timberframes. “But even with new technology we haven’t left our roots behind. We still use traditional mortise and tenon joints and authentic joinery which have retained solid engineering capacity for centuries.” And some of that old-world touch can be incorporated in other ways. “We have skilled carvers who can add unique features and detailing to the timbers for a very personalized look. One of our clients wanted sailboats carved into his roof trusses of his waterfront cottage. We pride ourselves on being able to provide that personal touch despite the technology.”

Once the CNC machines process the timbers to the size and specifications for the project, the finish is applied. A

clear coat gives a traditional pale Douglas fir look, but custom finishes like a circle-sawn antique finish, a distressed look or any tone of stain can be used to complement other design features like hardwood flooring or trim. Only then are the timbers ready to travel to the project site. “The timbers are at a furniture quality finish when they leave our facility,” says Jeff. “They are packaged in weather-proofed bundles and are carried by flatbed truck to the site along with the wall and roof systems that we manufacture.”

To read the full article, please open the attachment.

Just released, the 2014 Kootenay Best of Business winners.

Canadian Timberframes earns the Gold Best in Biz award within the Log Home/Timber Frame Company category!

We would like to thank our dedicated staff for all that they do on a daily basis to keep up with the demand & handling themselves with the utmost professionalism and bringing a second to none expertise & one of the highest levels of service within the industry! Also, a huge thank-you goes out to our incredible customers and partners, it truly is a pleasure doing business with you.

Just presented in the September, October Kootenay Business Magazine, the 2014 list of the top 50 Kootenay companies ranked by revenue. And yes, Canadian Timberframes made the list this year again, moving up our position from last year.

We will continue to offer our customers the utmost professional & skilled experience they have come to know & expect from us. Congratulations CTF on another stellar year and a sincere thank-you to all of our customers and business partners - we truely appreciate your business!

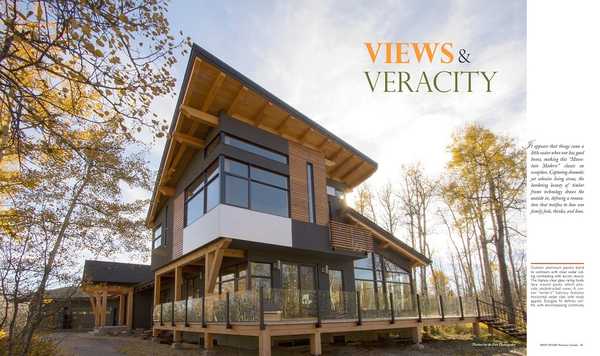

This timberframe renovation outside of Calgary was the subject of the feature article in the 2014 Winter edition of Best Homes Magazine, Western Canada.

They walk you through our Copperstone Project and its 1,800 sq ft timber addition; the design features of the home as well as its energy efficient focus.

Enjoy the read, then pop over to view additional photo's of this project.

"Perched on two acres of sun-dappled aspen, this bustling abode depicts a delightful interpretation of a tree house in the woods. “When the seasons change it’s really quite beautiful,” muses the homeowner, who wanted a space that was cozy, comfortable, and family-friendly.

Built by CopperStone Homes with a design by timber frame specialist Cheryl Link of Mountain Modern Studio, this collaborative effort encouraged an organic growth that left the original structure intact. Capturing an additional 1,800 square feet of open concept living, a spacious great room and dining room that host eighteen-foot vaulted ceilings (with an additional full basement beneath) engage a view-laden retreat that eloquently blends with its tranquil setting.

Located west of Calgary’s city limits, the home benefits from its timber frame enhancements that include corner windows of near curtain wall glass. White walls and bleached hard-woods freshen a decor infused with natural light and a seasonal landscape.

With building integrity and energy efficiency rivaling design in importance, lowe, argon-filled windows conduct passive solar heat, with spray foam insulation and a high-efficiency furnace providing a comfortable and well-insulated environment given generous glazing. The home’s air quality is enhanced by its Douglas fir ceiling, which acts as a natural filter and offers a better acoustical environment.

“At the end of the day, a home needs to be practical,” says Winkler, who prides his team on delivering superior craftsmanship beyond code and using pre-mium materials and building practices to ensure the quality and longevity of your renovation.

“A specific mindset is required when building a custom home,” says Winkler. “A story is told within a framework and part of this home’s story was bringing the outside in; in return we let some of the inside flow outwards. For example, the Douglas fir ceiling beams protrude seamlessly through drywall and stucco while supporting the massive roof overhang.”Delighted that they opted not to sell but stayed to achieve their dream home, the owners claim that their biggest gift in this experience was retaining the feel of the home where they raised their children. With stunning views of nature from every angle and well-placed art competing for attention with the outdoors, the family appreciated the teamwork they shared that was brought to life by uncompromising construction.

“It took just over a year to achieve our vision, and it was like watching art unfold.”

Check out the massive timber truss exterior on this industrial building below. The interior carries the timber structure throughout. To see the designs of this project follow this link to the project Richardson Camp

Stay tuned for more photo's on the ongoing construction of our current jobs.

Klaus, Senior Designer/Timber frame Technician is looking over the custom steel order before delivery to the construction site for our Kicking Horse Chalet project.

The methods of fastening the frame members can differ in custom timber frame homes usually design dictating method, where structural engineering does not play a factor. In traditional timber framing, mortise and tenon or more complex joints are usually fastened using only wooden pegs. But, the timber trusses designed for this chalet will incorporate steel joinery as seen in the picture for both structural and architectural purposes. It is amazing when braces are added to a simple post it can really dress up the whole area. Timber frame design is very flexible; depending on one’s taste or environment - there truly is a design for everyone.

Stay tuned and follow the project; as we move through the construction phase.

It was a busy morning at our mills & manufacturing facility we loaded three trucks that are heading across the country to a few of our projects under various stages of construction. The trucks are bound for Fernie, BC; Canmore, Alberta and the last off to Kenora, Ontario. But before they all head out, another heavy tarp will be added to each load to protect the timber components during trucking.

What’s under the tarps you ask?

The Fernie truck is the 3rd timberframe home we have shipped in the last 3 months to this destination. We were shipping the frame for a chalet as well as, the T&G for last 2 homes that are now ready for their flooring, walls & roof systems. Just in case you were curious….we were shipping 6 lifts of timberframe & 8 lifts of T&G on this truck.

The Canmore truck was shipping a complete timberframe package. The framing will start immediately; starting with the basement timbers then moving on to their main floor. The timbers shipped are highly polished, smooth furniture grade finish for this contemporary home. On the truck we loaded 9 lifts (ranging from 10-22ft in length) of timberframe components and one pallet of hardware.

The Kenora home had it’s timber raising already, so they are now ready to start their install of the floors, ceilings & timber deck. T&G shipped has a heavy lacquered finished with custom made heavy steel metal works for interior & exterior architectural finishes.

Canadian Timberframes (CTF) has recently enrolled into the Timber Products Inspection program. Timber Products Inspection, Inc. (TP) is an independent, third party woods product inspection, testing and consulting company with field representatives throughout North America. They provide professional inspection services as well as monthly auditing to all of their customers. Using TP, our customers will now have independent, professional third party assurance of our timber grades stamped on our timbers. Their grading rules are based upon ‘Standard methods for establishing stress grade for structural members used in log and timberframe buildings’ Standard ASTM D3957 a North American recognized standard used for both residential and commercial uses.

Walter Bramsleven, our Production and Logistics Manager says “we are excited to pass this high level of quality to our customers and we are one of the few of North American timberframe companies with this level of timber accreditation.”

One of the great benefits to our customers from this new program, is when a grade of timber is specified by an architect or engineer within their design, we can deliver on these requirements in house without adding additional costs or time, where other manufacturers would have to source this service; get tested & comply. Grading also provides a layer of protection for the manufacturer and homeowner by establishing definable levels of quality for the products being sold and marketed within the industry.

The Grading Process:

TP’s lumber experts, engineers and research scientists have developed an accredited program to define stress grades for the log and timber industry’s use. In this program, logs and timbers are visually inspected with qualified graders observing all the surfaces of the member for strength reducing characteristics. Graders must be TP personnel or individuals trained by TP at manufacturing facilities.

Manufacturing facilities with grade-marking privileges must have their graders certified and their performance is routinely monitored on an unannounced basis to assure conformance to the guidelines.

By providing this level of confidence and security to our customers it ensures 3 important measures: each piece has been visually inspected and graded – ensuring quality; it ensures all clients are delivered the quality of wood specified in their contract, and lastly; with the ongoing monthly surprise inspections by TP the quality & grading is always being inspected, validated and third party endorsed.

If you would like to know more about our program we are here to answer your questions. Please contact Walter Bramsleven at wbramsleven@canadiantimberframes.com

Regained optimism and paced growth mark another impressive year of new custom timberframe homes for Canadian Timberframes. says Jeff Bowes, President and Partner. It is exciting to be working with so many new clients, raring to build and to support this new demand CTF has been in ‘hiring’ mode since the start of the year.

We invite you to read our entire newsletter; we have featured a new exciting project that is in the design phase and 2 incredible projects in construction.

It all starts with a tree. And not just any tree. The best trees for building a timberframe home are tall with a tight, dense grain and beautiful natural colour. The best of the best is the Douglas fir, but even within that species some are better than others depending on where it grows.

Golden BC where Canadian Timberframes has it’s manufacturing facility, is in the heart of the best stands of interior-grown Douglas fir in North America,” says Jeff Bowes, president and partner at Canadian Timberframes Limited. “Douglas fir grows well in Oregon and Washington State but the Columbia Valley in the B.C. interior is at a higher elevation which causes slower growth and results in a tighter grain.” A tighter grain means stronger and more stable timbers.

Keep reading for the rest of ‘our’ process in building your timberframe cottage or home.

Local and sustainably harvested Douglas Fir timbers provided by Canadian Timberframes were just the start to helping this home become an energy efficient gem. The 4,172 sqft timberframe retreat has all the amenities, such as a complete home theater, open concept living space, outdoor kitchen, full bar and an in-ground hot tub with a waterfall. Outfitted with high end finishes and amenities this home proves that a spectacular home can also be a smart home. Please click to read the article.

In the wild west coast of Vancouver Island, is an outdoor lover’s dream and a surfer’s paradise. Here, wetsuit-clad adventurers brave the heaving Pacific Ocean swells while whale-watching tour boats, fishing boats, and kayakers crisscross its waters. The area abounds with hikers and campers, and bear and bird watchers, who have traversed Vancouver Island to embrace the wildness of the coast, its long sandy beaches, and its windswept temperate rainforest.

May has been a busy month for the Golden Cycling Club. First, the local trails were opened and cleared of their winter debris. With over 100km of trail spread throughout four trail systems, it can be a challenge to stay ahead of local cyclist.

Best recognized by their soaring great rooms and large walls of windows that allow the unobstructed views of cottage living; timber frame construction is becoming the choice of many cottage goers today. The architectural style is so versatile; whither you love a contemporary or more traditional feel; rustic charm or a more polished finish - custom timber frame homes can meet the needs of even the most distinguished.

“The benefit of timber frame construction is its ability to integrate larger, more open spaces,” says Jeff Bowes, president and partner at Canadian Timberframes Limited. “Timber frames let you remove interior structural walls for better sightlines of Muskoka’s stunning vistas while being beautiful in their own right.”

Canadian Timberframes is proud of our recent project: the new Bow Valley Parkway entrance in Banff National Park that we built. The impressive 65' X 3' upper log welcomes park visitors in true 'BC Style'. Enjoy reading the whole article.

Canadian Timberframes is featured in the publication: DOCKSIDE - THE BEST OF MUSKOKA. In this article by Sarah Fulton May, CTF is praised for its ability to incorporate timber into any scenery. Jeff Bowes, Partner and Director of Business Development interviewed as the expert in Muskoka timber living.

Winter has arrived at the hill top of Collingwood Ontario. The site of one of the most spectacular projects of the last year. We are pround to have been selected by UPSTREAM CONSTRUCTION on this truly amazing resort home. Look for more information on the open house that is scheduled for spring 2014.

Are you wondering what our company is up to? Sign up for our newsletter.